Flow meters let you keep a close eye on the precise amount of gas being consumed. Volumetric or mass-flow meters monitor gas volumes for custody transfer (Sm3/Nm3, energy value in megajoules), gas turbine efficiency monitoring and/or quality control.

We can measure flows of 1 million Nm3/h and above with accuracies to within 0.1%. Automatic (hourly, daily, weekly) reporting can include pressure, temperature, and energy value per standard cubic meter for billing.

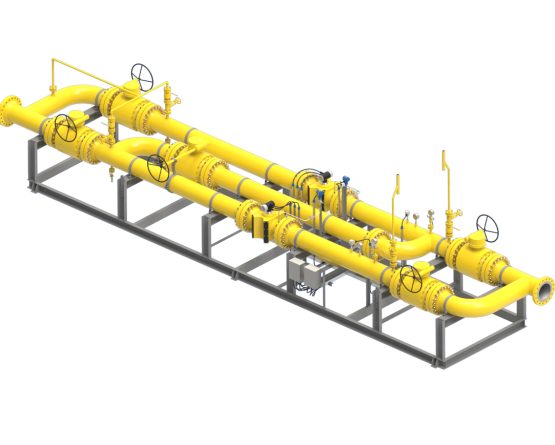

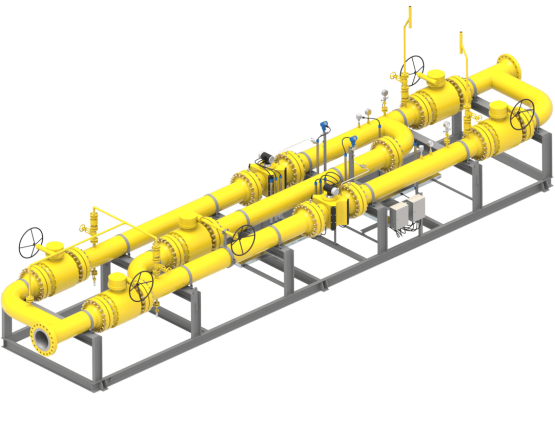

A flow computer can compensate measurements for temperatures and pressures, and a gas analyzer lets you calculate the correct energy intake. We offer various advanced measuring methods and layouts for easy operation and maintenance.

Options include:

- Various types of meters; Turbine, Rotor, Ultrasonic, Orifice, Coriolis, etc

- High pressure actual gas medium calibration

- Single or redundant metrology and control

- Parallel runs eliminate downtime

- Calibrated at operating pressure before delivery

- Approved to all relevant industry standards

EASIER

You get all the local and control-room instruments and controls you need to keep your operations running efficiently and safely.

Real-time monitoring lets you use live operational data for preventive and predictive maintenance schedules. And you have accurate measurements for transfer proving.

Automated reports are integrated into our software that help to prove measurements and make operators’ lives easier. The metering systems measurements can be used to calculate the amount of gas used and the cost of gas for custody transfer.

Measurements have the accuracies needed for correct fiscal and other records. You can measure operating and ambient temperatures to help keep operations safe and reliable in extreme environments from Siberia to the Sahara.

SMARTER

Skid mounted equipment allows for fast on-site erection. A bypass run lets you change meters without shutting down the plant, and a Z-loop configuration allows you to perform in-line accuracy checks of your meters. Start-up pipe spools and strainers protect the sensitive meter internals.

All our systems are easily accessible for maintenance.

We have market-leading software that automatically analyzes and reports the measurements from the metering section.

BETTER

We use high quality components from the industry’s top suppliers including Elster Instromet, Sick Maiak, Flow Meter Group, Emerson and Endress & Hauser. You can specify your exact system configuration, even down to the make and type of components.

Case studies

Dedication and hard work

Ras Al-Khair Power Plant (fuel gas system)

- What did our customer request?

-

The Saline Water Conversion Corporation is a Saudi Government Corporation responsible for producing electric power and desalinating seawater. The SWCC Ras Al Khair project was at the time the largest combined power and desalination plant in the world and won the prestigious “Desalination plant of the year” award in 2015. It is a landmark project for SWCC.

The plant converts more than 1 billion litres of seawater into potable water each day, transforming the potable water situation in Riyadh, one of the world’s fastest growing and most water-stressed cities. The plant also produces 2400 MWe of electricity for the Eastern Province of Saudi Arabia and helps to power the nearby Ma’aden/Alcoa Aluminium plant.

The power plant is gas & oil fired, and Petrogas won the contract for the fuel gas conditioning station with 1 million Nm3/h capacity for 12 gas turbines, along with the backup fuel oil system to ensure a high quality, reliable and continuous supply of fuel for the turbines. Waste heat and reverse osmosis are used to desalinate 1 billion litres of sea water per day. - Our solution

-

In close cooperation with the owners’ engineer Pöyry, we designed six identical blocks. Each had two mirrored gas conditioning systems including Emergency Shut-Down valves, filters, flow meters, heaters, pressure reducing systems for GTs and boilers, pressure boosting compressors and a high pressure gas buffer system. Petrogas built the skid-based system in workshops in the Netherlands and China, and erected and commissioned the system on site.

- What set the project apart?

-

Because Petrogas has both engineering and fabrication in-house, our customer benefitted from our practical experience in the initial basic design phase. The design was optimized before Petrogas built the skids, wrote the control software and performed the on-site commissioning.

The system can boost gas pressure for a prolonged period and can maintain gas supply for several minutes when the gas feed is interrupted to allow the turbines to switch to fuel oil. Petrogas played a substantial role in drawing up the operating philosophy between all these systems. - What were the project challenges?

-

“The sheer size of the project made it a challenge. The system is actually twelve complete 12” gas conditioning systems with 100% redundancy. The photo shows the stacks of the Water Bath Heaters, 36 in total.

Resources, planning, logistics between several workshops and dozens of suppliers all required a creative approach. The order came in 2011 when we already had a healthy backlog, and the order was worth about a year’s turnover. Petrogas successfully completed the job thanks to the dedication and hard work of our personnel and suppliers. “

- What did our customer request?

-

Our customer required a fuel gas conditioning station for the Al Diwaniya project. The station prepares and conditions the gas before it enters the turbine, ultimately to generate electricity. The conditioning entails filtering, heating and reducing the pressure.

- Our solution

-

Petrogas supplied the Fuel Gas Conditioning Station, including hardware and control systems. A fuel gas metering system measures the gas used, and a safety valve shuts down the gas supply in case of extreme pressures or temperatures.

- What set the project apart?

-

Petrogas also performed part of the overall engineering. From our experience in similar projects, we advised the customer to approach a number of things differently to improve safety and efficiency.

- What were the project challenges?

-

“Al Diwaniya is located around 250 km south of Baghdad, in a region with security risks. Thanks to our local network of qualified professionals we assembled and commissioned the system on site. An innovative design meant we could easily mount the skids against each other on site, leaving just the bolts and nuts to be tightened.”

Contact us

Would you like to discuss your project with our Experts? Please feel free to contact us.

Direct contact with our Experts

Your interest

Gas Metering